Hydroloop System

An economical and sustainable solution for commercial refrigeration.

Hydroloop System

TECHNOLOGY EXPLAINED

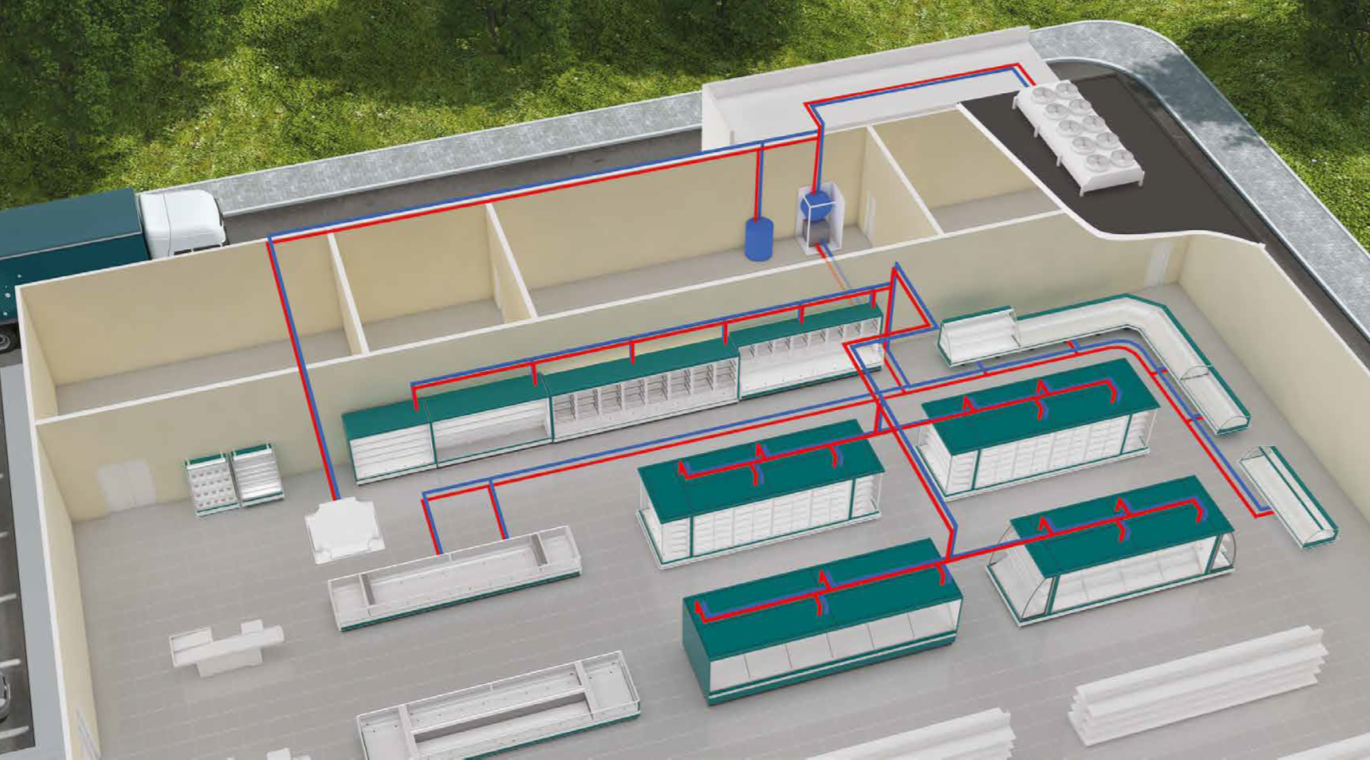

Hydroloop system is a cost-effective solution for shops, which allows connecting the plug-in refrigeration equipment to the liquid-cooled system, in which excess condensation heat is removed through liquid pipes to the exterior of a building. The closed-cycle liquid system with a water pump ensuring circulation and outdoor dry cooler is used for the effective heat recovery system.

Hydroloop solution can be connected to FREOR refrigeration multidecks, semi verticals, serve-over counters, and freezers. It is fully integrated refrigeration technology, which eliminates the need for complicated refrigeration systems and extremely simplifies system mounting works.

Environmentally-friendly propyl glycol solution is used for heat removal. Excess heat can also be used to warm up the shop during the cold season or to warm up the water. This innovative system guarantees high efficiency, faster shop installation, saves space, gives freedom of equipment relocation, uses smaller quantities of refrigerant, and is simpler to look after. Decentralized operation of refrigeration equipment allows for avoiding losses, which could be caused by an interruption in the central refrigeration system. All these advantages cut down costs and save your money.

-

Hydroloop Glycol System

It is a liquid-cooled system with a plate condenser.

- Dry cooler for thermal output in the summer period

- Pump station to ensure glycol circulation in a closed-loop

- Hot water tank (optional)

- Sales area heating (optional)

- Heat removal via glycol line.

This environmentally-sustainable solution allows the removal of heat from the shop through environmentally-friendly glycol line in the summer and additional use of the heat for warming up the shop and water in winter.

Decentralized operation of refrigeration equipment allows for avoiding losses, which could be caused by an interruption in the central refrigeration system.

Your chosen heating system can be additionally installed according to your needs.

Benefits

- No heat discharge into the shop

- A very small quantity of refrigerant

- Easy installation – saving costs

- No additional room height is needed to secure airflow

- Emitted heat can be used for shop heating

- Easy to integrate with various heating systems.

-

Hydroloop Hybrid System

It is a combined system fitted with air and plate condenser.

- Dry cooler for thermal output in the summer period

- Pump station to ensure glycol circulation in a closed-loop

- Hot water tank (optional)

- Sales area heating (optional)

- Heat removal via glycol line

- Direct heat output into the sales area in the winter period.

This solution allows combining two different heat removal systems with the possibility to switch over the regimes, which guarantees the easy use of excess heat for shop needs.

The heat is either emitted directly into the shop via air condenser mounted in the equipment (in the winter) or removed from the shop via glycol line to the outside (in the summer). It allows the heating of the shop when needed.

The direct heat output into the sales area in the winter period.

Benefits

- Direct warm air supply to the shop in winter

- Easy to install

- Easy to integrate with various heating systems

- Hydroloop system can be connected after installation of the refrigerators

- Reliable operation – in case of a fault in water circulation, heat is removed via air condenser on the top of the equipment.

Hydroloop WPI (Water Pump Integrated) System

Contact us-

The global food retail industry has been trending toward smaller store formats for several years already. Small-footprint store retailers usually face the issue of flexible trade area layout, space-saving, and optimal energy consumption, especially when it comes to refrigeration section planning. The smart refrigeration solution could not only solve the space problem but also help save money by reducing installation and operational costs.

Hydroloop WPI (Water Pump Integrated) System is the waterloop technology in which each of the refrigeration appliances contains an integrated small-sized circulatory water pump, eliminating the need for the main pump station in the waterloop system.

Hydroloop WPI System is a perfect solution for stores of smaller sales area size, such as petrol stations and convenience stores.

-

1. Circulatory water pump

-

Benefits

- Even more space-saving. No space is needed for the main pump station.

- Increased energy-efficiency. The individual high-efficiency integrated water pumps run in sync with the operation of compressors, maximum 16 h per day (24 h), compared to the main pump station running 24/7 in traditional Hydroloop System, resulting in approximately 30 % energy saving on glycol circulation operation.

- Simplicity & flexibility. The installation does not require an experienced technician – all you need is connecting equipment to simple hydraulic pipes and plugging into an outlet, giving store owners the flexibility to easier reorganize the units in case it is needed.

- Environmental sustainability. Running refrigerating appliances on R290 propane refrigerant and cooling the system with glycol creates a green system.

- Reliability. In case of a failure, only one refrigeration unit is affected, leaving food products safe and potential losses minimized.

-

1. Circulatory water pump

Hydroloop System Advantages

-

Energy efficiency

- Energy-efficient compressors save up to 25 % of the energy.

- Up to 80 %, a smaller quantity of the refrigerant is needed.

- Refrigerant leakage only 0–5 %, when remote – 10-15 %.

- Discharged condensation heat can be used to warm up the shop.

-

Environmentally-friendliness

- 95% less refrigerant leakage allows for reducing an impact on the environment.

- Small refrigerant quantities are needed if compared with a non-autonomous system.

- It can operate with R290 (GWP=3) refrigerant.

- Environmentally-friendly glycol solution is used.

-

Flexibility

- The system can be easily changed according to the store layout.

- It is easy to replace, add components or pieces of the equipment without stopping the whole system.

-

Easy installation and cost-effectiveness

- The system is easy and cheaper to install, compared with a remote system.

- No need for certified refrigeration experts for system installation.

- No need for the machinery room, which benefits in saving store space.

- The simple maintenance.

-

High reliability

- Every refrigerator operates as a separate unit; therefore, failure in one piece of equipment does not affect the others, and the potential loss of products is minimized.

- Every piece of equipment is set at the required temperature; automation ensures operation at the necessary intensity of the refrigeration equipment.

-

Low noise level

- Double sound isolation of the compressor and freezer minimize the noise level at the store.